Have Questions?

-

Genuine Parts

Guaranteed Authentic

-

Modification Specialists

Call for assistance

-

Mod Now, Pay Later

Financing Available

-

Save On Delivery

Free shipping on most orders over $199

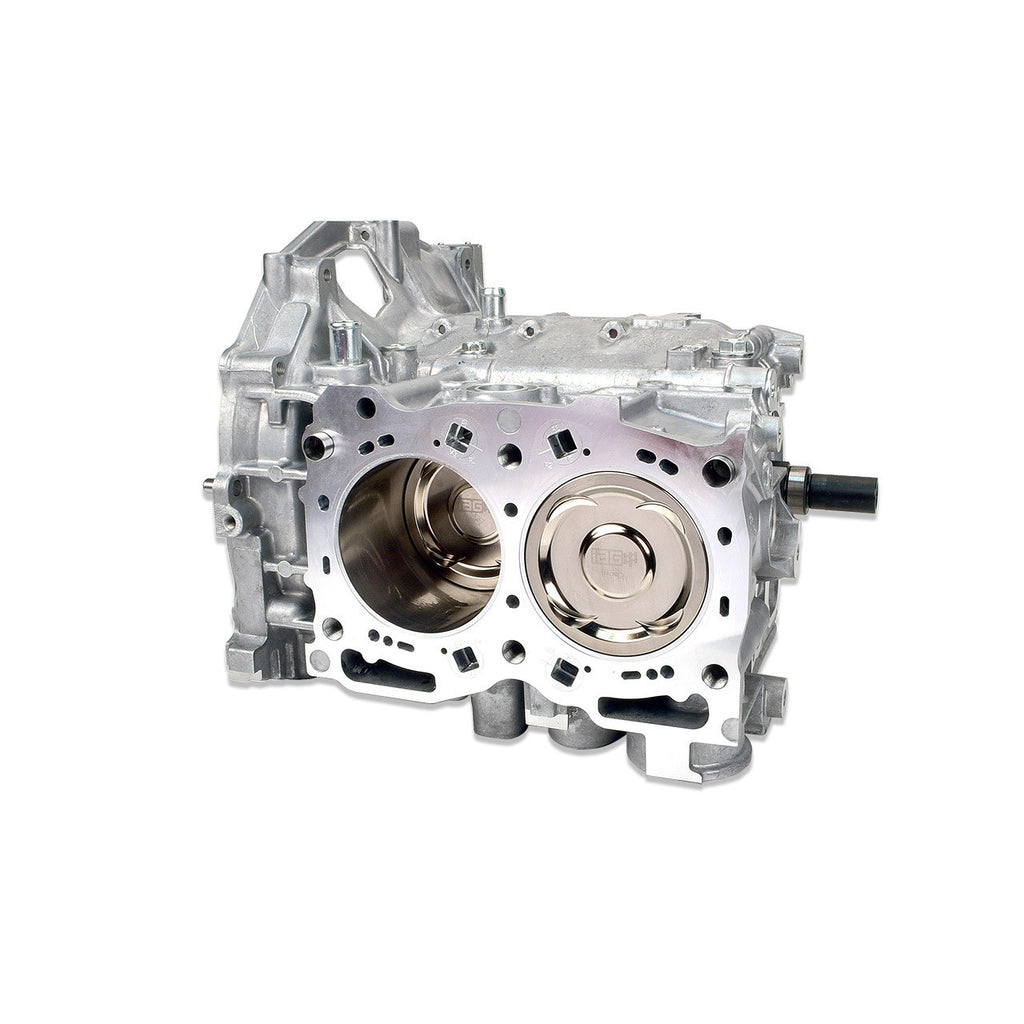

IAG 1150 2.5L Subaru Closed Deck Short Block (1150BHP) - Subaru WRX 2006-2014 / STi 2004-2021 / LGT 2005-2009 / FXT 2004-2013

IAG 1150 EJ25 2.5L SUBARU SHORT BLOCK

BUILT TO WITHSTAND HIGH HORSEPOWER DRAG RACING

The IAG 1150 Short Block is designed for those who plan to drag race their high horsepower Subarus regularly. While still a streetable block, the IAG 1150 is designed for the track. This block includes additional features to further strengthen the OEM case halves including Stage 4 Closed Decking and pinned mains secured with ARP case hardware. Our record-setting "Fire-Lock" Head Gasket system and 14mm head studs are used to ensure a tight seal even in extreme conditions. The IAG 1150 Short Block features IAG Spec "Tri-Beam" +2mm forged connecting rods. An IAG Spec Billet Crankshaft is used to support additional oiling and prevent main bearing distortion. The upgraded block, billet crank, connecting rods, race bearings, and forged pistons are able to support additional engine load produced by the largest turbochargers and the most demanding uses including competition drag racing.

BUILT WITH 100% NEW COMPONENTS

Every IAG Short Block is built with 100% new components. The modified case halves are assembled using an IAG-Spec Billet crankshaft that is matched to ACL or King race main bearings. Custom IAG TRI-BEAM +2mm connecting rods with ARP 625+ rod bolts are utilized, along with ACL or King race rod bearings. The case halves are sealed with OEM sealant and ARP main bolts. The IAG-Spec 99.75mm Custom Forged Pistons with .250" / .927" wrist pins as well as electroless nickel plated tops and ring area are chosen to finish the IAG 1150 Short Block.

IAG 1150 CLOSED DECK WITH FIRE-LOCK SYSTEM

The IAG 1150 Short Block starts with brand new Subaru 2.5L EJ25 engine case halves. The case halves are split and the main webs are CNC machined in our Haas VF-4SS CNC mill for 9.5mm pins to reduce distortion and movement of the case in extreme conditions. The case halves are then reassembled and IAG machines the case to accept the IAG CLOSED Deck Inserts that transform the block into a solid deck. The unique inserts feature small passages that allow needed coolant flow to the deck surface. The case halves are then CNC machined for our new Fire-Lock™ head gasket solution that is loosely derived from diesel technology where a counterbore step is machined around each cylinder bore allowing specially sized fire rings to drop into the machined area and head gasket bores. The IAG 1150 case is CNC drilled and tapped to fit 14mm head studs. Utilizing the new Fire-Lock™ gasket solution, along with larger IAG / ARP 14mm head studs, nuts, and washers reduce the chances of the heads lifting under extreme boost conditions. The short block is then Deck Plate bored and honed to 99.75mm in our in-house Sunnen SV-30 cylinder hone. IAG's in-house honing process is able to set custom piston to wall clearances to ensure performance and reliability.

OUR STRONGEST PISTONS EVER

The IAG 1150 Short Block uses our strongest pistons ever - The IAG-Spec 99.75mm Custom Forged Pistons with .250" / .927" wrist pins feature electroless nickel plated tops and ring area. IAG's custom pistons feature a lightweight design while increasing strength where you need it and are designed to work exclusively with the IAG +2mm Tri-Beam connecting rods. The wrist pin is short and is made from strong H13 tool steel. The pin piers are profiled to increase pin boss strength. Finally, IAG's pistons feature added gas ports that aid ring sealing in high boost conditions.

IAG 1150 Closed Deck EJ25 Short Block Includes:

- Case Halves -Converted to Closed Deck from brand new OEM Subaru case halves, bored and honed to 99.75mm.

- Pinned Mains -Machine case for 9.5mm pinned mains and lined honed.

- Fire-Lock -IAG Fire-Lock™ receiver groove machining, latest solution to prevent head gasket failure on high horsepower and high boost Subaru's - *IAG Fire-Lock™ head gaskets required

- Head Studs -Machined for 14mm Head Studs.

- Pistons -IAG-Spec JE FSR 99.75mm 2618 Forged Pistons, Electroless Nickel Plated Tops & Ring area, Ring Set, .250" / .927" H13 Wrist Pins, Clips, (Perfect Skirt Coating and Offset Wrist Pins)

- Connecting Rods -IAG-Spec +2mm Tri-Beam Connecting Rods with ARP 625+ Rod Bolts.

- Rod / Main Bearings -ACL or King Race Bearings.

- Crank -IAG-Spec Billet Crank

- Case / Main Bolts -ARP Main Bolts.

Compression Ratio:

- 8.5:1 on D Cylinder Heads (EJ255)

- 8.2:1 on B, V and W EJ257 Heads with standard thickness gasket.

Head Gasket Required:

- *IAG Fire-Lock™ .051" Head Gaskets with IAG-Spec Alloy Ring Set* PN# IAG-ENG-1741

Power: The IAG 1150 Short Block has a power output rating of 1150 BHP

Hardware / Seal Options:

Not planning on reusing your original short block service plugs and covers? IAG offers a simple comprehensive cover and seal kit that includes (1) Rear main seal, (3) OEM wrist pin plugs, (3) OEM wrist pin plug washers, (1) OEM separator cover, (6) OEM separator cover bolts, (1) OEM wrist pin service cover, (1) OEM wrist pin service cover O-ring and (2) OEM wrist pin service cover screws. *If you are reusing your original wrist pin service plugs and covers always replace the (3) OEM wrist pin plug washers and (1) wrist pin service cover O-ring before installing a short block to avoid potential leaks. *Never reuse a rear main seal on a new short block.

Head Gasket Options:

After years of research and development testing, the IAG Performance Fire-Lock™ head gasket is the newest solution to preventing head gasket failure on high horsepower and high boost Subaru EJ25 engines. This solution is loosely derived from diesel technology where a counterbore step is machined around each cylinder bore allowing specially sized fire rings to drop into the machined area and head gasket bores. The shims are designed to create a compression seal once the heads are installed and torqued into place. IAG fire rings are manufactured to a very strict tolerance from a proprietary alloy and are then put through a heat treatment process. The gaskets are manufactured from an asbestos-free composite raw material and feature a silicone based beading applied to critical areas to improve sealing around all water and oil passages. The combination of the alloy compression shims and gaskets assure maximum sealing for a Subaru EJ25 turbocharged engine.

*The IAG Fire-Lock™ gaskets require machine work for installation and are recommended for use with 14mm head stud hardware.

*The gaskets are sold in pairs with four Fire-Lock™ rings.

Features:

- Composite Material

- IAG-Spec Alloy Ring

- Specifically designed for 14mm Head Studs

- Silicone Beading

- 100mm Bore

- .051" Thickness

- Intended for High Horsepower, High Boost applications

- IAG ARP 14mm Head Studs Required

- Gaskets sold in pairs

Install Notes:

1. If a block or cylinder head was previously o-ringed the groove must be filled and resurfaced before using this type of gasket.

2. These gaskets require IAG ARP 14mm head studs to achieve the required torque necessary for proper installation.

3. Due to the required torque, any block that was previously honed will need to go to the next size overbore.

4. Future servicing will require cylinder head resurfacing due to an imprint left from the Fire-Lock™ rings.

Oil Pickup / Oil Baffle / Windage Tray Options:

The IAG Performance Subaru WRX / STI oil pickup was designed by Tigwerks to replace the OEM EJ25 oil pickup, which is prone to failure. It's a well-known fact that the OEM oil pickups often crack and fail which, in most cases, destroys your engine from lack of oil pressure. To avoid the cracking failures seen in the OEM oil pickup tubes, the Tigwerks oil pickup is manufactured from heavy-gauge steel tubing that is 3x thicker than OEM. Additionally, it features a flange machined from 3/8" 1018 CR steel to mate with the block, sealed with a Viton O-ring. The integrated heavy-duty mounting bracket uses two mounting points rather than the OEM single mounting point. Furthermore, the oil pickup features a formed bottom with an OEM style mesh screen for proper filtration. The TIG-welded oil pickup's increased material thickness, matched with the two-point heavy-duty mounting bracket, helps ensure that it does not fatigue and fail over time like an OEM unit.

The IAG Oil Control Baffle and Windage Tray System is designed to limit potential blow-by and prevent oil starvation in your Subaru's WRX / STI EJ engine during high rpm and high g-force driving. Through the use of Viton one-way flapper valves on our baffle and louvers in our windage tray, oil is prevented from reentering the upper crankcase area and is directed down into the oil pan to ensure plentiful supply to the oil pickup. IAG's integrated two-piece Oil Control Baffle and Windage Tray System is designed to work with our own oil pickup, as well as other oil pickups*. The baffle fits neatly in the engine crankcase area, allowing normal installation of the OEM oil pan and popular aftermarket pans*.

Oil Pickup & Baffle Install Notes

- EJ20 Subaru WRX engines require EJ25 oil pans for fitment

- IAG oil pickup spacer (Part# IAG-ENG-2081SP) is required when using IAG oil pickup with Killer B Oil Pan.

- *Does not work with Moroso oil pans or pickups

Oil Pump Options:

The 11mm Subaru Oil pump is one of the most popular off the shelf pumps to use on EJ25 engines. Originally equipped on the 2008-21 STI Dual AVCS engines, it provides an adequate amount of pressure and flow that fits the needs of many OE and built engines. But, as with almost anything, there is room for improvement.

Increasing oil flow volume and pressure in an EJ25 ensures that the bearings have sufficient oil film under all power levels and driving conditions. Additional oil flow to the engine provides a greater oil reserve to operate the AVCS solenoids and cam gears - giving you more consistent performance results.

The IAG Stage 2 CNC Ported 11mm oil pump was developed over years of servicing street and racing engines. In that time IAG has tested and utilized the majority of the popular Subaru oil pumps available on the market (JDM, Cosworth, ACL etc.) for customer, personal and racing vehicles.

Over the last few years if you wanted an upgraded oil pump over the stock 11mm you would either buy a hand ported model from a trusted source, or often an OEM JDM (Japanese Market) 12mm pump. We believe that we have developed a better alternative. The IAG Stage 2 CNC Ported 11mm oil pumps have shown through lab testing on a Spintron Machine that it will outperform a JDM 12mm.

The Stage 2 Oil pump is a cost effective solution that outperforms the market standards. This pump has been extensively tested on street cars, track cars, and on our in-house Spintron to ensure consistent and repeatable performance.

Each IAG Stage 2 oil pump starts life as an OEM spec 11mm oil pump, straight from Subaru. IAG completely disassembles the new oil pump including pulling the rotors, backing plate & pressure relief valve. Next, the main body is fixtured in our in-house 5-Axis Centroid CNC machine where the inlet and outlet passageways are CNC ported. This allows for a larger, more consistent pathway for the oil into and out of the gerotor internals and helps to prevent cavitation. The Oil Pump Outlet where it meets the engine block is also CNC “Port Matched”, for a perfect transition into the engine block. The Inlet and Outlet sides of the gerotor are also opened up on the CNC mill to reduce inlet side cavitation, and to reduce outlet side pressure drops.

The pressure relief valve piston is REM Polished, which provides a non-directional, low Ra, polished finish. This reduces friction, heat and possibility of the relief valve piston galling and sticking, a common failure point on the OEM pumps.

The piston is reinstalled and confirmed to operate correctly. The rotors are measured and checked to be within the manufacturer's specification - aka Blueprinted, and installed next. The pump is then put together with a light coating of assembly lube to reduce friction and scuffing and aid in priming on first start up.

Finally, the backing plate is installed. Loctite is added to the hardware, and each piece receives a painted mark after it is correctly torqued. The pump ships ready to install, with all hardware and seals required for installation.

Quality Guaranteed

Available 24 Month/24,000 Mile Warranty*

IAG stands behind every hand-built engine they produce. IAG's Standard Short Block Workmanship Warranty covers your short block for 12 months or 12,000 miles. They have also teamed up with a selection of IAG Certified Installation Facilities which offer up to a 24 month/24,000 mile workmanship warranty when the engine is purchased, installed, and tuned by that IAG Certified Installer.

Returns may be accepted within 14 days of purchase pending Return Merchandise Authorization (RMA). No returns or cancellations on special order items. All returns will be charged a 20% restocking fee, no exceptions.

To be eligible for a return, your item must be unused and in the same condition that you received it. It must also be in the original packaging. Item must be able to be resold as new.

Several types of goods are exempt from being returned. Hazardous materials, fluids, greases, chemicals, and clothing are not able to return.

Free shipping is available within the lower 48 states for most orders totaling $199 or more. A free shipping option will be available during checkout. This offer is for delivery address in the continental United States and excludes shipments going to Alaska, Hawaii, Military Boxes, and items that require freight shipping.

Processing Time

Patterson Performance stocks a large quantity of items at any given time. Some items may require drop shipping from one of our various distributors. In stock items will ship within 1-2 business days. If you're needing your product quickly, please contact us to verify product availability before placing your order. Orders requiring additional verification (security concerns, incorrect information, etc.) may need additional processing time. Estimated shipping dates are not guaranteed and are subject to change based on inventory levels and manufacturer lead times. Backordered items are shipped immediately once available.

Items ship daily, If the item you ordered is not in stock, a member of our team will contact you via email / phone.

Patterson Performance will only ship to an address that varies from your billing address if payment is made via Paypal or a financing partner.

Patterson Performance ships from multiple warehouses throughout the United States, and sometimes from manufacturers overseas.

You can simply contact us via email / telephone for a live inventory check

Find more information at www.P65Warnings.ca.gov.